Product introduction

The machine is used for grinding waste lithium batteries (positive and negative material).

Working principle

The main structure of the machine is equipped with rolling bearings at both ends to support the main shaft, which is driven by the motor through the belt to drive the main shaft and the turbine fastened on the main shaft to rotate at high speed. The turbine and the grinding block on the screen ring form a reasonable and compact structure, so that the raw materials entering the machine are closely rubbed in the rotating air flow and the impact of the air flow occurs on the inner edge of the turbine blade, and regrinding is carried out in the gap between the blade and the grinding block. In this process, the turbine absorbs a large amount of air, which plays the purpose of cooling the machine abrasive and conveying fine powder. The fineness of crushing actually obtained also depends on the predetermined material, the shape and size of the screen hole, and the passing amount of material and air.

Product features

1. Use the new grinding disc design, with high output, strong wear resistance and twice the service life of the ordinary grinding disc.

2. The newly designed special bearing achieves high speed, and only one driving motor is used to ensure efficient impact grinding, saving mechanical operation time and engineering control.

3. It is easy to install and maintain. It can be cleaned by opening the door cover.

4. The grinding process is fully sealed without dust leakage.

5. The discharge particle size is adjustable, and the adjustment of grinding clearance is simple. It can be accurately adjusted only by using feeler gauge and adjusting bolt.

6. The cooling system of the main engine can adopt the double cooling system of air and water.

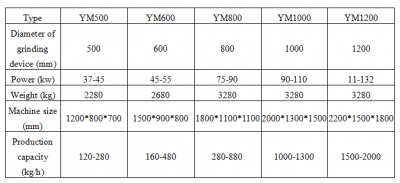

Technical parameter