Capacity:

15-550t/h

Customization:

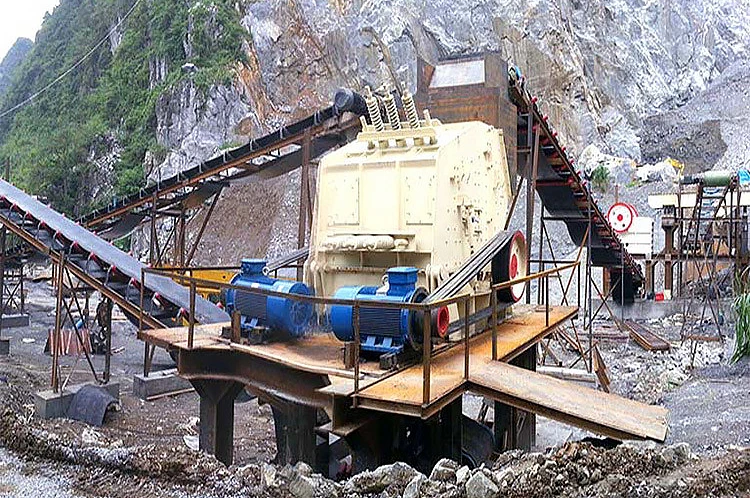

Flexible adjustment of the discharge particle size with a wide adjustment range. The rotor speed or the gap between the impact plate and the hammer can be adjusted to effectively control the discharge particle size, with good particle shape, which is very suitable for fine crushing operations.

After the material enters the crushing chamber, it is crushed by the impact of the hammer on the high-speed rotating rotor, and at the same time it is thrown to the impact plate installed above the rotor and is crushed again. The material is repeatedly impacted, impacted, and the stones collide and rub against each other in the crushing chamber until it is crushed to the required particle size and discharged.

It is widely used in medium and fine crushing of materials with medium hardness and below (such as limestone, slag, coke, coal, slag, etc.), especially suitable for the production of construction aggregates and road surface materials.

Large crushing ratio, good product particle shape (mostly cubic), high production capacity, and easy maintenance.

The hammer and impact plate wear quickly, and are not suitable for processing highly abrasive materials.

| Model | Main power(kw) | Processing capacity(t/h) | Weight(t) | Dimensions(mm) |

| PF-807 | 30-45 | 15-30 | 8 | 2210*1490*2670 |

| PF-1007 | 37-55 | 30-50 | 9 | 2400*1558*2660 |

| PF-1010 | 55-75 | 50-80 | 12 | 2400*2250*2620 |

| PF-1210 | 110-132 | 70-120 | 15 | 2690*2338*2890 |

| PF-1214 | 132-160 | 130-180 | 18 | 2690*2688*2890 |

| PF-1310 | 110-160 | 80-140 | 16 | 2780*2478*2855 |

| PF-1315 | 180-260 | 160-250 | 19 | 3096*3273*2667 |

| PF-1415 | 220-315 | 220-450 | 27 | 3745*3022*3519 |

| PF-1520 | 315-440 | 300-550 | 36 | 3581*3560*3865 |